What factors affect the final pricing for bulk candle tins ordered in bulk?

When buying bulk candle tins, the final price you pay can be affected by various factors. Bulk orders offer the advantage of lower unit costs, but that doesn’t mean pricing is always clear-cut. Whether you’re a candle manufacturer, retailer, or distributor, it’s essential to understand the potential factors that influence pricing. In this article, we’ll break down these factors and take a closer look at how the production and delivery of bulk candle jars are priced.

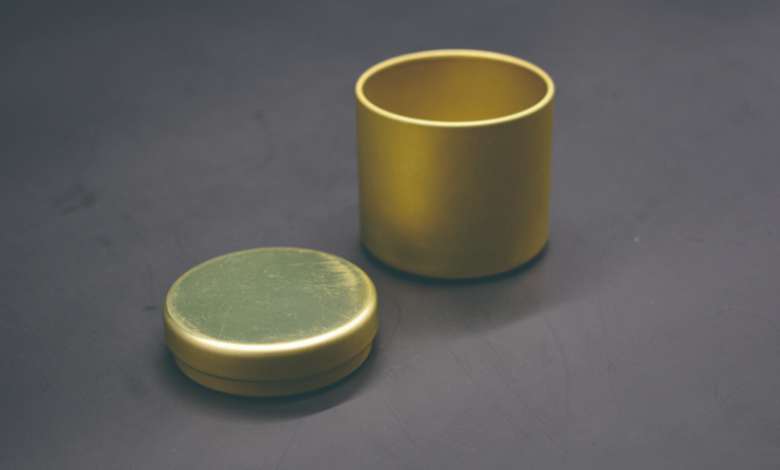

Bulk Candle Tins: Material Selection and Quality

The material used is the first and most crucial factor in bulk candle tin pricing. Most candle tins are made from metal, such as tinplate, aluminum, or steel. Tinplate is the most common because it’s cost-effective and can handle candle wax without noticeable degradation. However, the quality and grade of the material will directly affect the price.

Higher-quality metals, such as food-grade aluminum or premium tinplate, will increase costs. Additionally, the thickness of the material can affect durability, especially when the tin is designed for high-end or luxury candles. Custom finishes, such as smooth, brushed, or embossed surfaces, can also require unique materials or additional processing, increasing the price. It is critical to balance material quality and price requirements for bulk candle tins, as higher-grade materials may provide better protection for the candles but may require a higher upfront cost.

See also: The Rising Demand for At-Home STD Check-Up Services in Dubai

Customization Options for Bulk Candle Tins

Customization is another important aspect of pricing when ordering candle tins in bulk, and it refers to any design elements beyond the standard, unbranded tins. These may include custom sizes, embossed logos, or intricate artwork printed directly onto the tin.

The more detailed and complex the customization, the higher the price. For example, custom printing can add significant costs, especially if multiple colors are involved. Factors such as the complexity of the design or the need for complex embossing or debossing processes can also increase the total production cost. It is essential to weigh the additional expense of customization against the branding benefits that custom bulk candle tins can bring to your product. Custom designs create a unique identity for a brand but naturally affect the final price.

Order Quantity and Size

The number of bulk candle tins you order directly affects the pricing structure. Generally, the higher the order quantity, the lower the unit price. Bulk orders allow manufacturers to streamline production and reduce overhead costs, which can be passed on to customers. Larger orders reduce the unit price, but manufacturers may still have minimum order requirements. These minimums will vary depending on the type of bulk candle tins and the level of customization required. Smaller orders, even in bulk, will result in a higher price point due to production setup costs. Planning the correct quantity to fit your business model and minimize unnecessary costs is critical when considering bulk orders.

Manufacturing Complexity and Lead Time

The manufacturing complexity of bulk candle tins can also affect the final price. Simple, mass-produced jars with standard sizes and finishes are generally less expensive because the manufacturing process is simple and can be scaled up effectively. However, including custom designs, complex shapes, or special features can make production more complicated—the more steps involved in the manufacturing process, the more expensive the final product. Lead time also plays a role here: the longer it takes to produce, the more resources may be tied up in the order, which can affect the cost. When ordering bulk candle tins, it is essential to evaluate the balance between complexity, quality, and turnaround time to ensure you meet the needs of your business within your budget.

Shipping and Logistics Costs

Shipping and logistics costs can add an unexpected but essential layer to the total price of bulk candle tins. Since the jars are often manufactured overseas, international shipping costs can significantly impact the final cost. Factors such as production origin, destination, and shipping method (air vs. ocean) can all affect shipping costs. Additionally, ordering candle tins in bulk requires more extensive packaging to ensure the jars are shipped safely. The weight and size of the shipment, as well as the use of unique packaging materials, can all increase costs. When considering a bulk order, these costs must be planned and factored into the final pricing.

Key Takeaways for Bulk Candle tin Pricing

Understanding the factors that influence the final pricing of bulk candle tins is essential to making an informed purchasing decision. From material selection and customization options to manufacturing complexity, shipping costs, and regulatory compliance, each element can impact the final price of your order. By carefully evaluating these factors and considering your business needs, you can ensure that your bulk candle tin order fits your budget and quality expectations.